Starting Simulation Environment Using Aspen Hysis 2014.

Aspen Hysis 2014.1

1.

Starting Hysis

o

Click

Start

o Click Program | Aspen Engineering Suits | Aspen Hysis 2014.1

2.

Creating New Case

o

Select

File| New | Case or Press Control N

o

This

Open Simulation Basic Manager.

3.

Adding New Components

o

Click

Add button

o

Will

bring component List view.

o

Select

the desired components

o

Double

click or click Add Pure on desired components. Give Component List Name.

4.

Selecting a Fluid Package

o

Select

the Fluid Package Tab in simulation Manager

o

Click

Add Button to create New simulation Package

o

Select

the desired fluid package from the list.

o

Give

Fluid package Name

5.

Selecting Thermodynamic Properties

|

System |

Recommended Proeperty method |

|

TEG Dehydration |

PR |

|

Sour Water |

PR, Sour

PR |

|

Cryogenic Gas Processing |

PR PRSV |

|

Air Separation |

PR PRSV |

|

Atm Crude Tower |

PR GS |

|

Vac Tower |

PR

PROption GS |

|

Ethylene Tower |

Lee Kesler plocker |

|

High H2 System |

PR ZJ GS |

|

Reservoir System |

Steam Package |

|

Hydrate Inhibition |

PR |

|

Chemical System |

Activity Model, PRSV |

|

HF Alkylation |

PRSV,

NRTL |

6.

Entering Simulation Environment

o

Click

on Enter Simulation Environment or Icon

7.

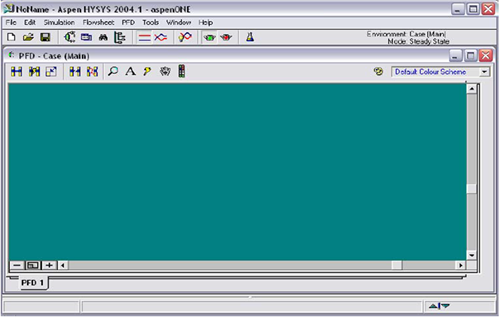

Simulation Environment.

o

The

simulation Environment will be like as below

8.

Adding a Stream

o

Object

Palette : Click on Object Palette button on flow sheet or Press F4

o

Click

On blue arrow button on Object palette window or Select the Flow sheet Menu and

click Add Material Stream

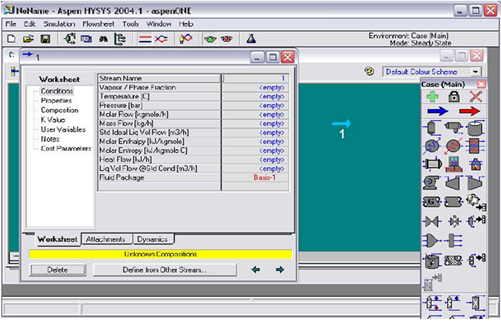

9.

Adding Stream Properties

o

Double

click on stream, Material detail property window will Open as shown

below.

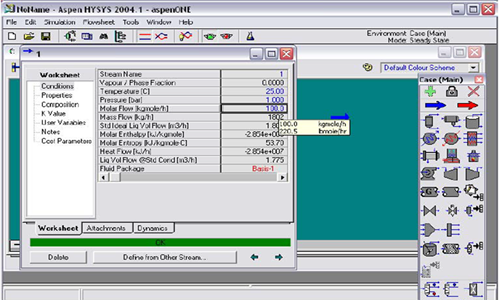

o Require to give minimum Four properties 1. Composition, 2. Temperature, 3. Pressure, 4. Flow rate

o

Click

on Composition, enter the mole fraction of composition.

o Click on Condition, Enter Temperature and Pressure

o

After

entering flow rate, Green bar indicate Condition for solving equation is

fulfilled.

o

Also

Stream Colour is changed to Dark Blue.

Comments

Post a Comment